Loughborough University

As part of our aims to not just to restore 21c11 / 35011 to original condition, we also endeavour to promote education in technology and engineering associated with the preservation and restoration of heritage steam.

In 2020/21 we ran two projects with the Loughborough University with the 2020/21 Project 1 looking at the external and the 2020/21 Project 2 looking at the internal aerodynamics of a Merchant Navy, using Computational Fluid Dynamics (CFD) to place our locomotive in a virtual wind tunnel.

Our goal with these projects is to explore conditions in the smokebox and the exhaust clearance, with the possibility of making improvements on the design.

Following the success of the 2020/21 collaboration we are running further projects in 2021/22 to look at aspects of the blastpipe design in more detail. The intention is to compare the potential performance of a Bulleid-Lemaître blastpipe with other concepts such as the Giesl and Lempor ejectors.

2020/21 Project 1 - Improving flow over the locomotive and improved visibility

In the first Loughborough project we are exploring, using CFD, some concepts for improving the flow over the locomotive to improve visibility, with some initial modelling to try and baseline the CFD against the existing design. The work involves the external aerodynamics of the locomotive and the atmospheric air flow and its interaction with the buoyant exhaust plume with the engine running at various speeds. The students have developed a model of the locomotive based on generic data made available by GSNLRS and made suitable approximations to enable high-quality CFD predictions.

By studying videos on YouTube of steam locomotives at speed, focussing on air-smoothed Bulleid Light Pacifics, they were able to develop some understanding of when to expect obscuration of the drivers forward vision to occur. From there, they simulated conditions where obscuration is observed, as well as ones where it is not, in order to validate their modelling.

Moving on from this, they are looking at developing an understanding of how the smoke deflectors impact the flows, looking at the effect of the ducting around the chimney exit as well as exploring ideas that J. Click proposed, and finally looking at the impact of different exhaust designs on smoke clearance (Lempor and Giesl-Lempor-Rapley).

Video 1. Simulation of exhaust from locomotive running at 80MPH, with a 20mph crosswind, 20,000lb/hr steam flow - Coloured loco temperature Celsius.

Video 2. Simulation of exhaust from locomotive running at 80MPH, with a 20mph crosswind, 20,000lb/hr steam flow - Coloured loco density.

2020/21 Project 2 - Blastpipe Design

In the second Loughborough project, we are looking at the blastpipe design to compare the potential performance of the envisaged Lemaître blastpipe with other concepts such as the Lempor and Giesl-Lempor-

Rapley ejectors.

After some initial problems deciding what to analyse, the students have focused on simulating the tests conducted on 35022 at the Rugby Locomotive plant in 1952/3; these tests were very well instrumented and controlled, providing an excellent suite of data to validate the CFD. Additionally, that two different exhaust designs were tested (multi-nozzle Lemaître and single nozzle/chimney arrangement) provides the opportunity to thoroughly validate the methodology used, giving confidence that the effects of the various changes in geometry are well captured.

This is important, as it gives us confidence that any performance change predicted due to modifications in the design is a real improvement. Currently the students have conducted the simulations against the Rugby data for the two designs, getting very good agreement against the test data.

The next step is exploring alternate designs to see what improvements they could bring to our locomotive’s performance; anecdotal evidence suggests, for example, that fitting the Giesl Ejector to 34092 increased its power by nearly 20%, bringing it in line with a Merchant Navy.

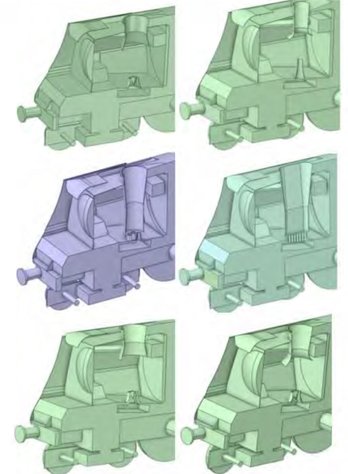

Figure 2. Some of the exhausts trialled in CFD (Clockwise from tiop left: Original design, single jet arrangement, Rapley-giesel-Lampor, Rebuilt design, Original Design with de Laval nozzles, Lempor.)

Video 3. Merchant Navy - Original smokebox design -flows

2021/22 Project 1 - Further detail of Blastpipe design

The proposed project for this year is to look at aspects of the blastpipe design in more detail. The intention is to compare the potential performance of a Bulleid-Lemaître blastpipe with other concepts such as the Giesl and Lempor ejectors.

Suggested taks include :

- Developing 2D and 3D simplified geometry models of Bulleid-Lemaître, Giesl and Ellis ejectors based on generic data made available by GSNLRS and making suitable approximations to enable high-quality CFD predictions.

-

Develop boundary conditions for engine running at different speeds and external flow conditions (ambient pressure and cross-flow).

-

Develop a mesh and decide the right physics models to describe the flow in the blastpipe.

-

Decide validation strategy to build up the scientific credibility of simulations.

-

Develop post-processing tools for high-quality result visualisations.

-

Develop full 3D geometry models and meshes for Bulleid-Lemaître, Giesl and Ellis blast pipes and make thorough comparison with experimental data supplied by GSNLRS.

-

Study the effect of mesh on predicted flows.

-

Study the effect of turbulence model on predicted flows.

-

Study the effect of exhaust temperature and exhaust emission velocity on exhaust flow properties.

-

Design explorations to improve exhaust plume properties: comparison of Bulleid-Lemaître, Giesl and Lempor blast pipe designs. Modifications to the design will need to fit within the current space-envelope of the locomotive.

-

Integrated 3D CFD model of blastpipe and smokebox.

We would like to reassure our members that this is not our society deciding to discard the original design and pursue something different, it is more an opportunity to explore the art of the possible, whilst exposing the next generation of engineers to our locomotive.

Further details of the all the project outcomes will be published here following their peer review.